CT Application Examples from the Plastics Industry – Replacement of Conventional Measuring Equipment

3D coordinate measuring machines with sensor Computed tomography are now widely used in the plastics industry and are increasingly replacing standard measuring equipment. Precision in measurement coupled with a speed that is unattainable for conventional measuring instruments are particularly characteristic of the TomoScope® XS Plus systems with integrated workpiece changer.

Today, the devices are used in production monitoring, quality assurance and in the development of injection molding tools, for example, to calculate tool corrections directly with the FormCorrect software package in the WinWerth® measurement software.

Smaller plastic gears can also be inspected in a production cycle of a few seconds per workpiece. 96 gears can be detected together in just 2.5 minutes. The measuring point clouds are automatically assigned, the entire tooth geometry is measured and all gears are checked for defects such as burrs or cavities.

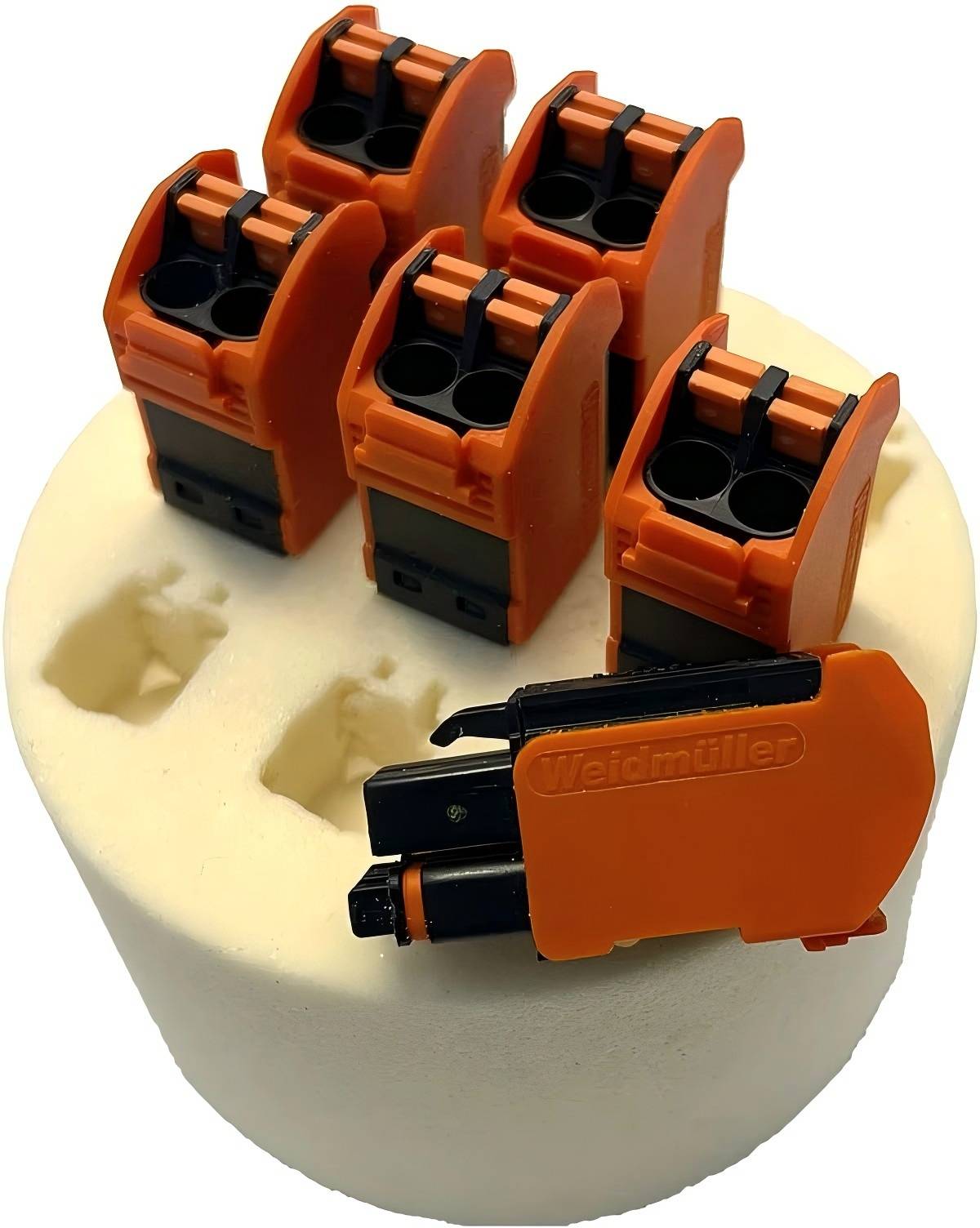

For example, the dimensional accuracy of the metal and plastic components can be measured in the installed state on connectors and cable connectors, and the connecting terminals can be inspected fully automatically for defects and burrs. The burr detection software procedure integrated as an option in WinWerth® provides a color-coded deviation representation of the ridge as well as the maximum ridge length.

Industrial computed tomography is used to check the dimensional accuracy of the assembly and the individual components