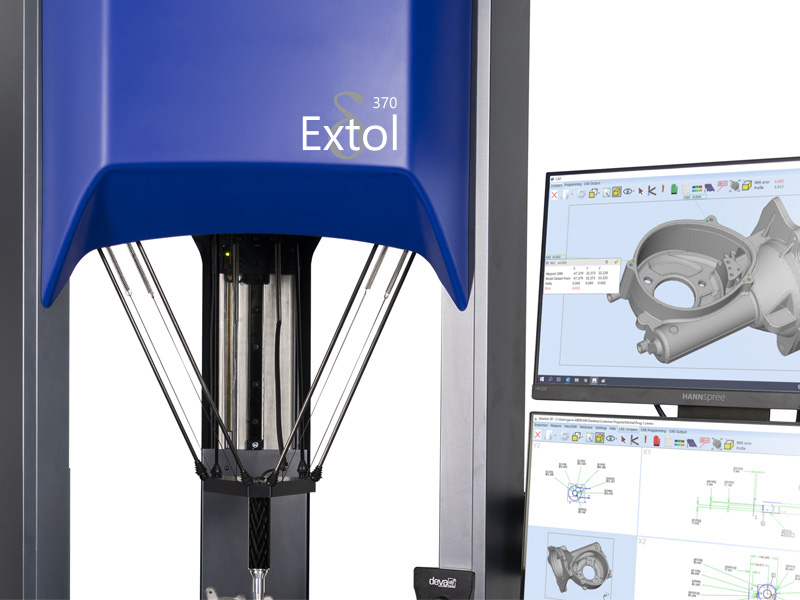

Extol CNC CMM

Next Generation Of Shop Floor Hardened, Non-Cartesian CMM

True to Aberlink's heritage for innovation, the Extol is the world's first CMM to utilise a delta mechanism.

CMM, a coordinate measuring machine, is a high-precision measuring instrument. It can accurately measure the size, shape, position and other parameters of an object in three dimensions. Moreover, the accuracy of CMM is unquestionable, and it can meet the needs of various industries for high-precision measurement.

The Extol CMM, which meets the needs of automated quality control on the shop floor, is a non-Cartesian coordinate system measuring machine with a triangular mechanism that combines high efficiency and precision with a robust, reliable and flexible design that is capable of operating 24/7 on the machining center, in the fabrication shop, or in the precision measuring room, making it an ideal tool for quality control in the enterprise.

Automatization

Extol series CMM adopts high-precision sensors and measuring system, which can be accurate to the micron level. Moreover, it is automated, digital and intelligent, which greatly improves measurement efficiency and accuracy.

The automatic tool offset correction provided by Aberlink 3D software complements the attributes of the Extol, allowing it to be used in a manufacturing environment as part of a fully automated production process.

Delta Motion Mechanism

Conventional CMMs use three mutually perpendicular Cartesian coordinate systems, which often require large granite shafts or heavy castings to ensure rigidity, and this heavy construction can impede repeatability, in particular by causing hysteresis, which is a lag between the applied and detached forces that can lead to deformation of the structure. The EXTOL with its Delta motion mechanism, consisting of three servo motors that move the probe through six carbon fiber rods, offers fast measurement speeds and high repeatability accuracy compared to traditional CMMs.

Technical Features

1. High speed and efficiency

Unique triangular mechanical structure, parallel motion mechanism to replace the traditional CMM axes of the movement unit, fast speed, making the measurement efficiency is unparalleled.

2. No need for air source

Fully sealed circulating mechanical bearings not only have excellent anti-dust and wear resistance, but also do not require an air source, with a wide range of workshop adaptability.

3. Vibration free

Superior belt drive and linear bearings reduce the impact of vibration on the machine, thus enabling longer styli and uncompromising accuracy during measurement.

4. Harsh environments

A fully automatic temperature compensation system allows EXTOL to operate in harsh shop floor environments and ensures accurate results.

5. Automated interfaces

Combining automatic machine tool offset compensation and automation interfaces, EXTOL can be fully and seamlessly integrated into automated machining cells for flexibility and agility.